Download this page as a Matlab LiveScript

Table of contents

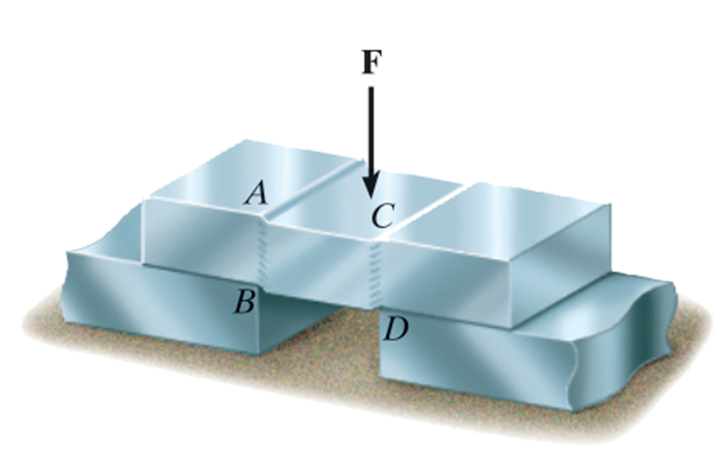

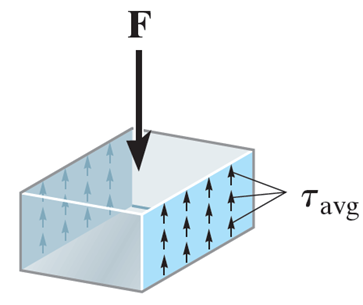

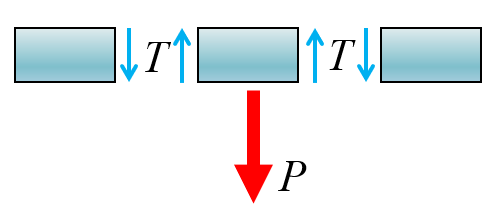

The average shear stress is given by

τ = T A \tau =\dfrac{T}{A} τ = A T where T T T A A A

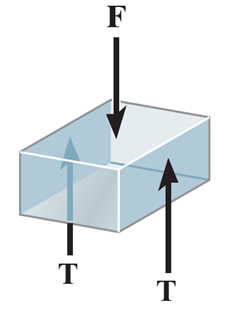

Determine the shear stress in the cylindrical pin with a cross sectional area of A A A P P P

Solution

FBD of the pin

{ P − 2 T = 0 τ = T A \left\lbrace \begin{array}{ll}

P-2T=0 & \\

\tau =\dfrac{T}{A} &

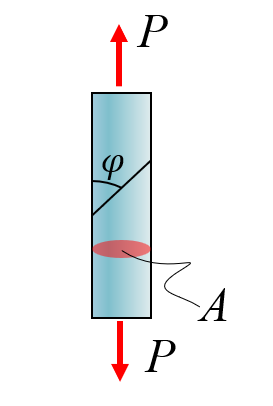

\end{array}\right. { P − 2 T = 0 τ = A T ⇒ T = P 2 , τ = P 2 A \Rightarrow T=\dfrac{P}{2},\tau =\dfrac{P}{2A} ⇒ T = 2 P , τ = 2 A P Determine the stresses in the cut at an angle φ \varphi φ

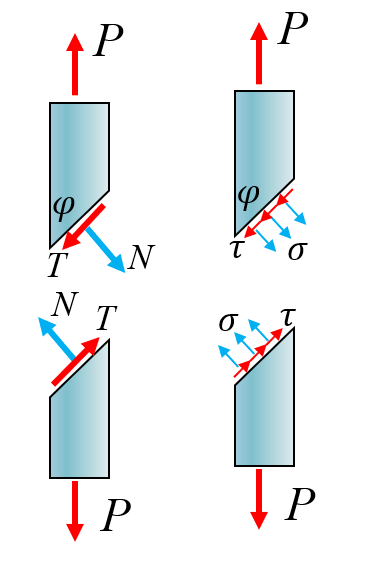

Solution

Cut and FBD

N x = N cos φ , N y = N sin φ T x = T sin φ , T y = T cos φ σ φ = N A / sin φ , τ φ = T A / sin φ

\def\arraystretch{2.5}

\begin{array}{cc}

N_x = N \cos\varphi,\; N_y=N\sin\varphi \\

T_x = T \sin\varphi,\; T_y=T\cos\varphi \\

\sigma_\varphi = \dfrac{N}{A/\sin\varphi},\quad

\tau_\varphi = \dfrac{T}{A/\sin\varphi} \\

\end{array}

N x = N cos φ , N y = N sin φ T x = T sin φ , T y = T cos φ σ φ = A / sin φ N , τ φ = A / sin φ T { N sin φ + T cos φ − P = 0 − N cos φ + T sin φ = 0 σ φ = N A / sin φ τ φ = T A / sin φ

\def\arraystretch{1.5}

\left\lbrace \begin{array}{ll}

N\;\sin \varphi +T\;\cos \varphi -P=0 & \\

-N\;\cos \varphi +T\;\sin \varphi =0 & \\

\sigma_{\varphi } =\dfrac{N}{A/\sin \varphi } & \\

\tau_{\varphi } =\dfrac{T}{A/\sin \varphi } &

\end{array}\right.

⎩ ⎨ ⎧ N sin φ + T cos φ − P = 0 − N cos φ + T sin φ = 0 σ φ = A / sin φ N τ φ = A / sin φ T ⇒ N = P sin φ , T = P sin φ , σ φ = P sin 2 φ A , τ φ = P sin φ cos φ A \Rightarrow N=P\;\sin \varphi ,\quad T=P\;\sin \varphi ,\quad \sigma_{\varphi } =\dfrac{P\;\sin^2 \varphi }{A} ,\quad \tau_{\varphi } =\dfrac{P\;\sin \varphi \;\cos \varphi }{A} ⇒ N = P sin φ , T = P sin φ , σ φ = A P sin 2 φ , τ φ = A P sin φ cos φ clear

syms N T varphi P A sigma_varphi tau_varphi

eq = [N*sin (varphi) + T*cos (varphi) - P == 0

-N*cos (varphi) + T*sin (varphi) == 0

sigma_varphi == N/(A/sin (varphi))

tau_varphi == T/(A/sin (varphi))]( T cos ( φ ) − P + N sin ( φ ) = 0 T sin ( φ ) − N cos ( φ ) = 0 σ φ = N sin ( φ ) A τ φ = T sin ( φ ) A )

\left(\begin{array}{c}

T\,\cos \left(\varphi \right)-P+N\,\sin \left(\varphi \right)=0\\

T\,\sin \left(\varphi \right)-N\,\cos \left(\varphi \right)=0\\

\sigma_{\varphi } =\frac{N\,\sin \left(\varphi \right)}{A}\\

\tau_{\varphi } =\frac{T\,\sin \left(\varphi \right)}{A}

\end{array}\right)

⎝ ⎛ T cos ( φ ) − P + N sin ( φ ) = 0 T sin ( φ ) − N cos ( φ ) = 0 σ φ = A N s i n ( φ ) τ φ = A T s i n ( φ ) ⎠ ⎞ [N,T,sigma_varphi,tau_varphi] = solve(eq, [N,T,sigma_varphi,tau_varphi]);

simplify([N,T,sigma_varphi,tau_varphi])( P sin ( φ ) P cos ( φ ) P sin ( φ ) 2 A P sin ( 2 φ ) 2 A )

\left(\begin{array}{cccc}

P\,\sin \left(\varphi \right) & P\,\cos \left(\varphi \right) & \frac{P\,{\sin \left(\varphi \right)}^2 }{A} & \frac{P\,\sin \left(2\,\varphi \right)}{2\,A}

\end{array}\right)

( P sin ( φ ) P cos ( φ ) A P s i n ( φ ) 2 2 A P s i n ( 2 φ ) ) P = 1 ; A = 1 ;

figure ; hold on

fplot(subs(N), [0 ,pi /2 ], 'linewidth' , 2 , 'DisplayName' , '$N/P$' )

fplot(subs(T), [0 ,pi /2 ], 'linewidth' , 2 , 'DisplayName' , '$T/P$' )

fplot(subs(sigma_varphi), [0 ,pi /2 ], 'linewidth' , 2 , 'DisplayName' , '$\sigma_\varphi A / P$' )

fplot(subs(tau_varphi), [0 ,pi /2 ], 'linewidth' , 2 , 'DisplayName' , '$\tau_\varphi A / P$' )

legend ('Interpreter' ,'latex' )

xlabel('$\varphi$' , 'Interpreter' ,'latex' )As we can see, the maximum shear stress is at π 4 = 45 ∘ \frac{\pi }{4}={45}^{\circ } 4 π = 45 ∘

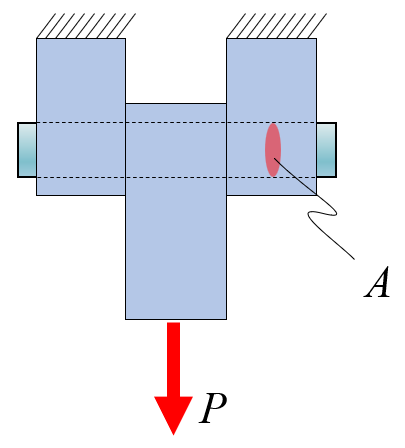

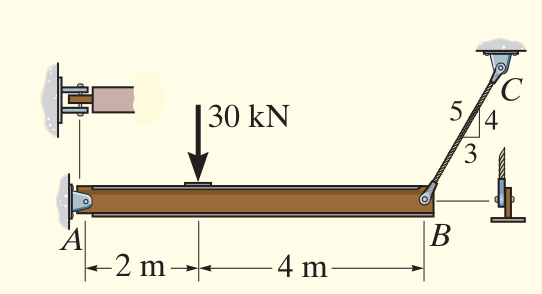

Dimension the pin in A and in B is the maximum allowable shear stress is 180MPa, use a safety factor of 1.5.

Solution

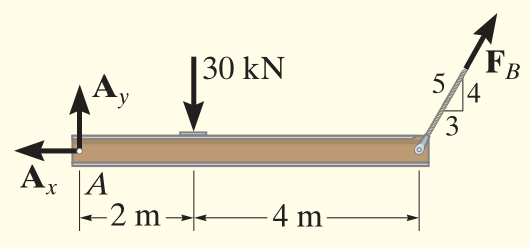

FBD of the rigid beam.

Equilibrium equations give:

{ ∑ M A = 0 : F By r AB − F G r AG = 0 ⇒ F B 4 5 ⋅ 6 − 30000 ⋅ 2 = 0 → : F Bx − A x = 0 ⇒ F B 3 5 = A x ↑ : A y − F G + F By ⇒ A y = 30000 − F B 4 5 \left\lbrace \begin{array}{ll}

\sum M_A =0:F_{\textrm{By} } r_{\textrm{AB} } -F_G r_{\textrm{AG} } =0 & \Rightarrow F_B \dfrac{4}{5}\cdot 6-30000\cdot 2=0\\

\to :F_{\textrm{Bx} } -A_x =0 & \Rightarrow F_B \dfrac{3}{5}=A_x \\

\uparrow :A_y -F_G +F_{\textrm{By} } & \Rightarrow A_y =30000-F_B \dfrac{4}{5}

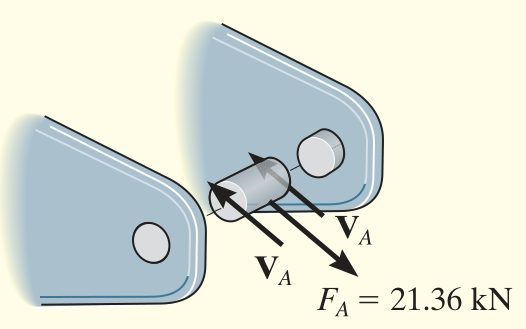

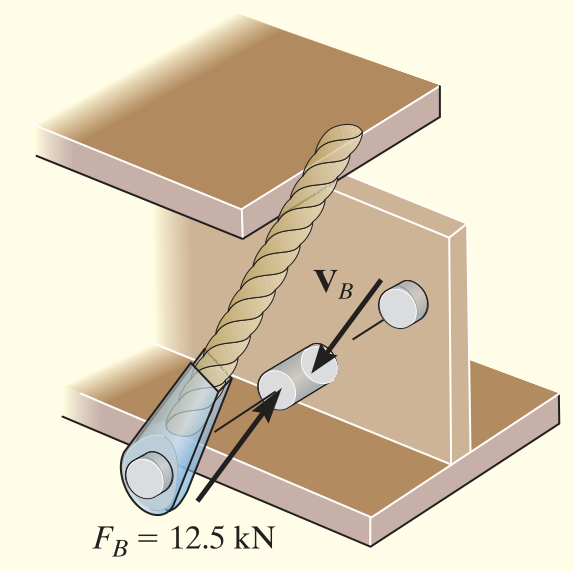

\end{array}\right. ⎩ ⎨ ⎧ ∑ M A = 0 : F By r AB − F G r AG = 0 →: F Bx − A x = 0 ↑: A y − F G + F By ⇒ F B 5 4 ⋅ 6 − 30000 ⋅ 2 = 0 ⇒ F B 5 3 = A x ⇒ A y = 30000 − F B 5 4 F A = ∣ [ A x , A y ] ∣ = A x 2 + A y 2 F_A =|\left\lbrack A_x ,A_y \right\rbrack |=\sqrt{A_x^2 +A_y^2 } F A = ∣ [ A x , A y ] ∣ = A x 2 + A y 2 V A = 1 2 F A V_A =\dfrac{1}{2}F_A V A = 2 1 F A τ A = V A A A ⇒ A A = τ A V A = ( d A 2 ) 2 π \tau_A =\dfrac{V_A }{A_A }\Rightarrow A_A =\dfrac{\tau_A }{V_A }={\left(\dfrac{d_A }{2}\right)}^2 \pi τ A = A A V A ⇒ A A = V A τ A = ( 2 d A ) 2 π V B = F B V_B =F_B V B = F B τ B = V B A B = V B ( d B 2 ) 2 π \tau_B =\dfrac{V_B }{A_B }=\dfrac{V_B }{ {\left(\dfrac{d_B }{2}\right)}^2 \pi } τ B = A B V B = ( 2 d B ) 2 π V B clear

syms d_A positive

F_A = 21360 tau = 180e6 /1.5 V_A = 1 /2 *F_A;

d_A = solve(tau == V_A / ( (d_A/2 )^2 *pi ) , d_A)d_A =

89 500 π

\frac{\sqrt{89} }{500\,\sqrt{\pi } }

500 π 89 d_A = vpa(d_A) d_A =

0.010645107772184811425477557121826

0.010645107772184811425477557121826

0.010645107772184811425477557121826 d_A = d_A*1000 d_A =

10.645107772184811425477557121826

10.645107772184811425477557121826

10.645107772184811425477557121826 syms d_B positive

V_B = 12500 ;

d_B = solve(tau == V_B/( (d_B/2 )^2 *pi ), d_B)d_B =

600 1200 π

\frac{\sqrt{600} }{1200\,\sqrt{\pi } }

1200 π 600 d_B = vpa(d_B) d_B =

0.01151647164904451597550815486773

0.01151647164904451597550815486773

0.01151647164904451597550815486773 d_B = d_B*1000 d_B =

11.51647164904451597550815486773

11.51647164904451597550815486773

11.51647164904451597550815486773 Conclusion: The pin in A needs to be at least 11mm and the pin in B needs to be at least 12mm. For easier manufacturing, just use 12mm pins in both connections.