Table of contents

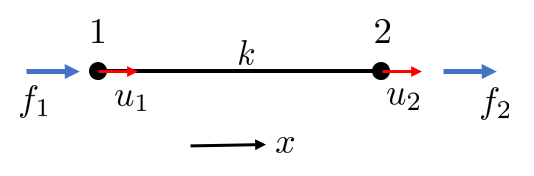

One dimensional rod with two displacements and two forces.

Recall a spring force: , now we apply this on our case

where . With and we can write

or on matrix form

or

where is known as the element stiffness matrix.

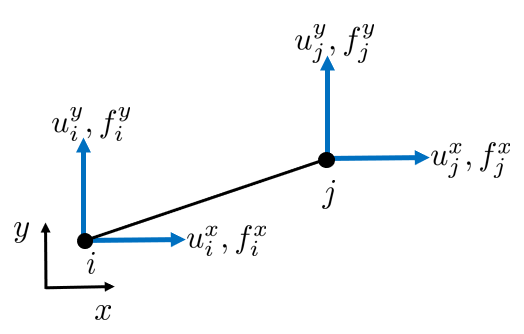

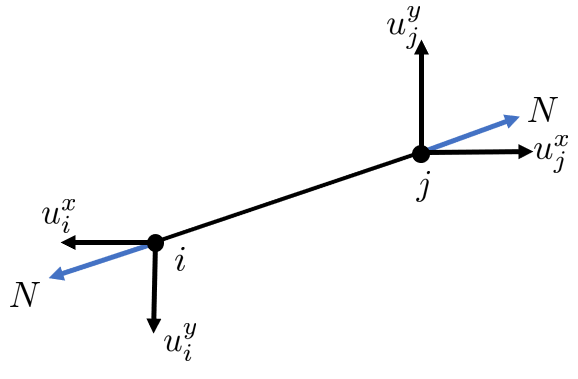

Now, consider some arbitrary rod in a two dimensional setting.

Each node can be translated in the x- and y-direction and each node can carry loads in x- and y-directions.

We shall derive the element stiffness matrix for this rod, but it is easier to first derive it in local coordinates and then transform it into the global coordinates.

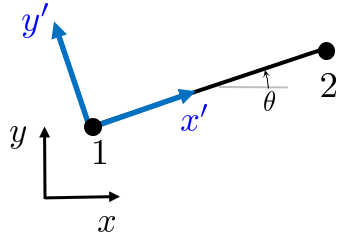

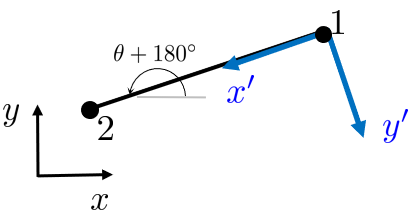

Each rod has a local coordinate system and and local node numbers and . The local coordinate system is rotated compared to the global coordinate system, and the angle is denoted by . In the local coordinates we have

We have zero force normal to the rod since the rod only can carry axial forces. The above relation can be written on matrix form

or

known as the local element stiffness matrix.

We need a way to transform to and . In other words, we need a relation between and and

which on matrix form is

or

where is known as the transformation matrix, and we recognize the rotation matrix within. The transformation matrix has interesting properties: and .

Using the transformation matrix we can transform local quantities to global

or

where is known as the element stiffness matrix.

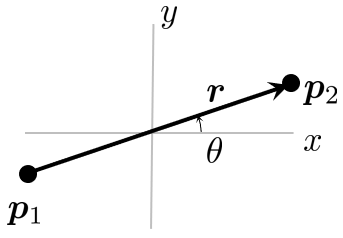

One could determine the angle . But there is a cheaper way. Let define the rod vector such that

then the normalized vector

such that we get

and

We note that the element stiffness matrix is symmetric.

Does it matter how the rod vector is defined? The vector can be defined either by or and we get two situations.

It turns out (which is easily verifiable) that is independent of the how the rod vector (or angle ) is defined, i.e., both alternatives yield the same result.

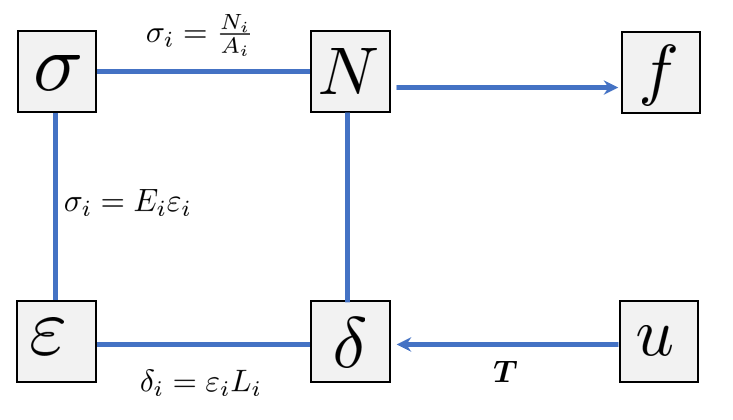

The deformation of the rod is given by

where is called the transformation vector.

We have the rod element rod force

and the element load vector (or reaction forces)

The element strain is obtained by

and the stress by

note that the length of the element can be easily computed by

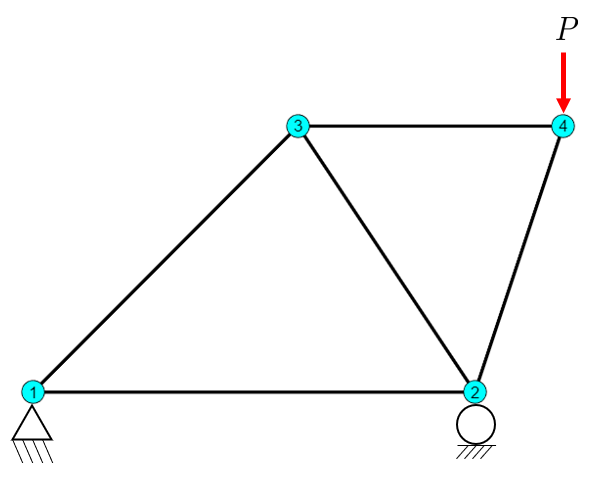

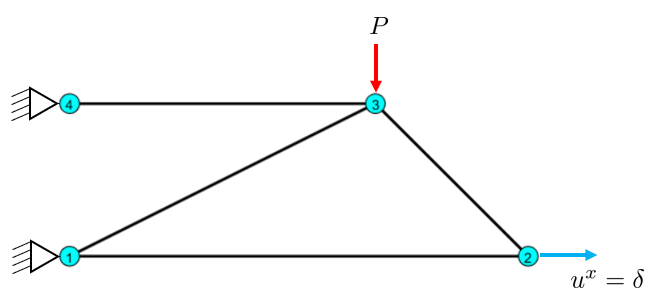

Let us analyze a structure as an example and look at the implementation details in Matlab.

The structure is loaded by a force with the topology given by

P = [0 0

5 0

3 3

6 3]*100; % mm

edges = [1 2

1 3

2 3

2 4

3 4];Problem statement:

Given the structure above, determine all displacements, member forces, deformations, strains and stresses as well as reaction forces in the supports.

Solution

The coordinates are given by the variables P and the edges define the node connectivity.

The order of the columns in nodes is not important.

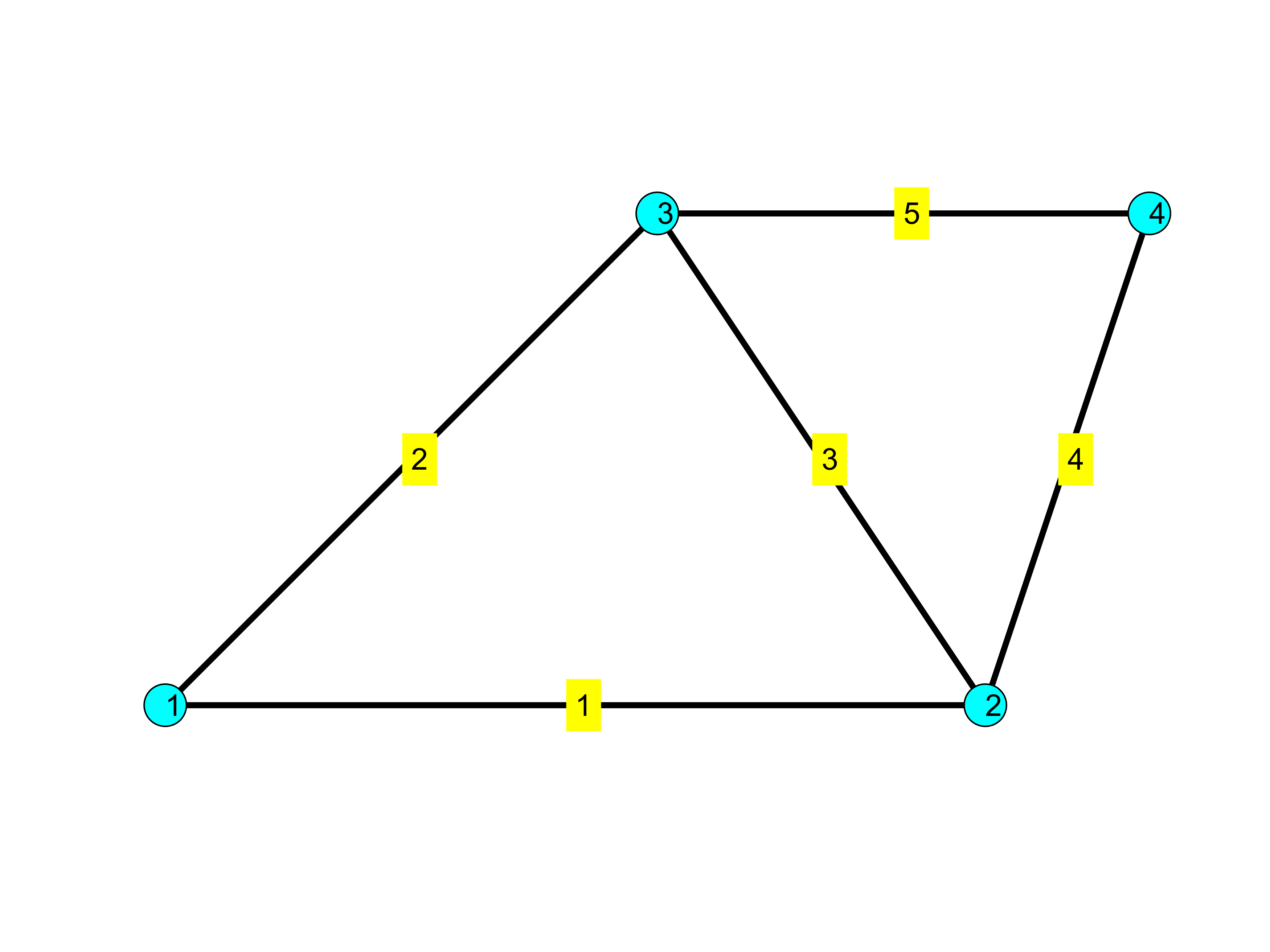

Using the topological data from above, we can visualize the truss structure in Matlab as follows:

figure

hold on

patch('Faces',edges,'Vertices',P,'LineWidth',2)

plot(P(:,1),P(:,2),'ok','MarkerFaceColor','c','MarkerSize',14)

nnod = size(P,1);

text(P(:,1)-0.05,P(:,2),cellstr(num2str([1:nnod]')))

axis equal

axis off

for i=1:5

inod = edges(i,:);

xm = mean(P(inod,1));

ym = mean(P(inod,2));

text(xm,ym,num2str(i),'backgroundColor','y')

end

The total number of degrees of freedom (or equations), is given by

where is the number of nodes and is the number of local degrees of freedom per node.

The global displacement field and load field are given by

With the resulting linear system taking the form of

The unknown displacements are computed by establishing the global stiffness matrix (system matrix) . Creating the linear system (28) and solving for . This is done by the following steps:

Initialize the stiffness matrix, i.e., set it to zero, .

Loop over all elements, and for each element:

Compute the element stiffness matrix,

Add the element stiffness matrix into the global stiffness matrix

Add the element load vector to the global load vector

Apply boundary conditions

Solve the linear system

We begin with some preliminaries and initialize the global system matrix and vectors using the number of degrees of freedom.

nele = 5nnod = 4dofs = 8S = zeros(dofs, dofs);

f = zeros(dofs,1);

u = f;

Sprim = [1 0 -1 0

0 0 0 0

-1 0 1 0

0 0 0 0];

Ltot = 0; %Total length of the structure.

E = 210000*ones(nele,1); % Young's modulus

A = 4*6*ones(nele,1); % Cross sectional areaElement 1

We begin by computing which global degrees of freedom correspond to our first element.

inod = 1x2

1 2The node numbers correspond to degrees of freedom, for our problem we have two, i.e., and translation. The data structure of ieqs is the same as for the displacements and loads above.

ieqs = 1x4

1 0 3 0ieqs = 1x4

1 2 3 4Computing the element stiffness matrix

p1 = 1x2

0 0p2 = 1x2

500 0r = 1x2

500 0L = 500Ltot = 500er = 1x2

1 0LT = 4x4

1 0 0 0

0 1 0 0

0 0 1 0

0 0 0 1k = 10080Se = 4x4

10080 0 -10080 0

0 0 0 0

-10080 0 10080 0

0 0 0 0Assembly process

The element stiffness matrix needs to be added to the global stiffness matrix . We need to ensure that the correct components from the element matrix are mapped to the corresponding components of the global stiffness matrix. This is done using the previously computed list of degrees of freedom, stored in the variable ieqs. We append (add) the stiffness contributions using

S = 8x8

10080 0 -10080 0 0 0 0 0

0 0 0 0 0 0 0 0

-10080 0 10080 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0This is the simplest form of assembly in code. It is easy to read and understand. It is however not very efficient for very large problems with hundreds of thousands of elements. So there exists other methods of dealing with this. But that is a topic for a course in high performance computing.

The rest of the elements are dealt with in an automated manner by executing the above lines of code for each element number, iel. This is done using the for loop:

iel = 2

L = 424.2641

Ltot = 924.2641

er = 1x2

0.7071 0.7071

k = 1.1879e+04

Se = 4x4

1.0e+03 *

5.9397 5.9397 -5.9397 -5.9397

5.9397 5.9397 -5.9397 -5.9397

-5.9397 -5.9397 5.9397 5.9397

-5.9397 -5.9397 5.9397 5.9397

S = 8x8

1.0e+04 *

1.6020 0.5940 -1.0080 0 -0.5940 -0.5940 0 0

0.5940 0.5940 0 0 -0.5940 -0.5940 0 0

-1.0080 0 1.0080 0 0 0 0 0

0 0 0 0 0 0 0 0

-0.5940 -0.5940 0 0 0.5940 0.5940 0 0

-0.5940 -0.5940 0 0 0.5940 0.5940 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

iel = 3

L = 360.5551

Ltot = 1.2848e+03

er = 1x2

-0.5547 0.8321

k = 1.3978e+04

Se = 4x4

1.0e+03 *

4.3011 -6.4516 -4.3011 6.4516

-6.4516 9.6774 6.4516 -9.6774

-4.3011 6.4516 4.3011 -6.4516

6.4516 -9.6774 -6.4516 9.6774

S = 8x8

1.0e+04 *

1.6020 0.5940 -1.0080 0 -0.5940 -0.5940 0 0

0.5940 0.5940 0 0 -0.5940 -0.5940 0 0

-1.0080 0 1.4381 -0.6452 -0.4301 0.6452 0 0

0 0 -0.6452 0.9677 0.6452 -0.9677 0 0

-0.5940 -0.5940 -0.4301 0.6452 1.0241 -0.0512 0 0

-0.5940 -0.5940 0.6452 -0.9677 -0.0512 1.5617 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

iel = 4

L = 316.2278

Ltot = 1.6010e+03

er = 1x2

0.3162 0.9487

k = 1.5938e+04

Se = 4x4

1.0e+04 *

0.1594 0.4781 -0.1594 -0.4781

0.4781 1.4344 -0.4781 -1.4344

-0.1594 -0.4781 0.1594 0.4781

-0.4781 -1.4344 0.4781 1.4344

S = 8x8

1.0e+04 *

1.6020 0.5940 -1.0080 0 -0.5940 -0.5940 0 0

0.5940 0.5940 0 0 -0.5940 -0.5940 0 0

-1.0080 0 1.5975 -0.1670 -0.4301 0.6452 -0.1594 -0.4781

0 0 -0.1670 2.4021 0.6452 -0.9677 -0.4781 -1.4344

-0.5940 -0.5940 -0.4301 0.6452 1.0241 -0.0512 0 0

-0.5940 -0.5940 0.6452 -0.9677 -0.0512 1.5617 0 0

0 0 -0.1594 -0.4781 0 0 0.1594 0.4781

0 0 -0.4781 -1.4344 0 0 0.4781 1.4344

iel = 5

L = 300

Ltot = 1.9010e+03

er = 1x2

1 0

k = 16800

Se = 4x4

16800 0 -16800 0

0 0 0 0

-16800 0 16800 0

0 0 0 0

S = 8x8

1.0e+04 *

1.6020 0.5940 -1.0080 0 -0.5940 -0.5940 0 0

0.5940 0.5940 0 0 -0.5940 -0.5940 0 0

-1.0080 0 1.5975 -0.1670 -0.4301 0.6452 -0.1594 -0.4781

0 0 -0.1670 2.4021 0.6452 -0.9677 -0.4781 -1.4344

-0.5940 -0.5940 -0.4301 0.6452 2.7041 -0.0512 -1.6800 0

-0.5940 -0.5940 0.6452 -0.9677 -0.0512 1.5617 0 0

0 0 -0.1594 -0.4781 -1.6800 0 1.8394 0.4781

0 0 -0.4781 -1.4344 0 0 0.4781 1.4344The resulting system , however, is singular. In mechanical terms, it contains rigid body motions. In mathematical terms, it has an infinite amount of solutions. To alleviate these rigid body motions, we need to clamp down the mechanical system by introducing boundary conditions which pose enough constraints on the displacements such that rigid body motions are prohibited. This is done for instance by eliminating equations, i.e., rows and columns corresponding to the degrees of freedom where the displacements are known. Solving the reduced system gives a unique solution.

Note that special treatment of the right-hand side is required in cases where the displacements are non-zero. See the section on Truss Analysis for details.

We assign the known boundary conditions and loads.

presc = [1 2 4]; % prescribed degrees of freedom

u(presc) = 0;

f(2*4) = -10000; % a single load at node 4 in the y-direction

free = setdiff(1:dofs, presc); % Free DOFs

u(free) = S(free,free)\f(free) % Solving the systemu = 8x1

0

0

-0.1984

0

0.2467

0.0901

0.4451

-0.9116We can separate the x- and y-components of the displacements into a two column matrix for easier handling in the visualization step below.

U = 4x2

0 0

-0.1984 0

0.2467 0.0901

0.4451 -0.9116We can also compute the resultant of the nodal displacement since it usually is of interest when evaluating requirements. We do this be computing the 2-norm of each row of the matrix (using the vectorized approach of course).

UR = 4x1

0

0.1984

0.2626

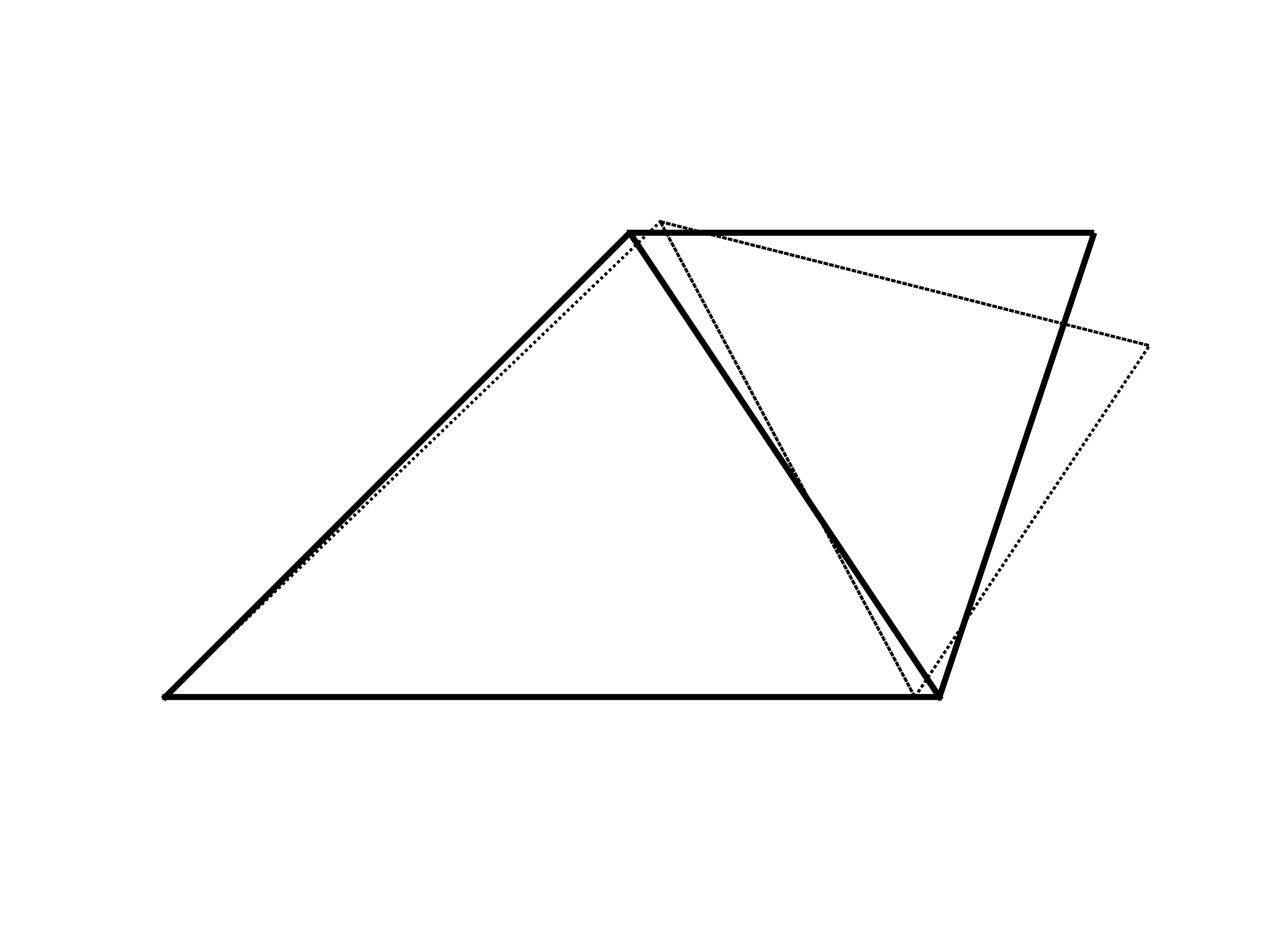

1.0145Visualize displacements

figure

hold on

patch('Faces',edges,'Vertices',P,'LineWidth',2)

patch('Faces',edges,'Vertices',P+U*80,'LineWidth',1,'LineStyle',':')

axis equal

axis off

The generated displacement field (dashed line) is scaled up by a factor of 80 since the displacements are otherwise too small to see.

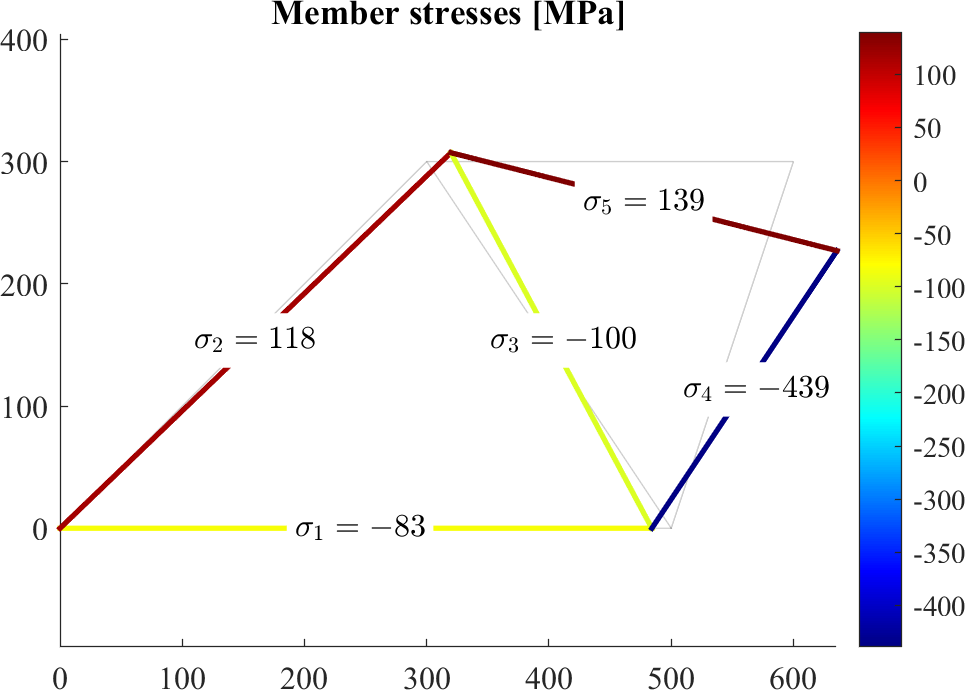

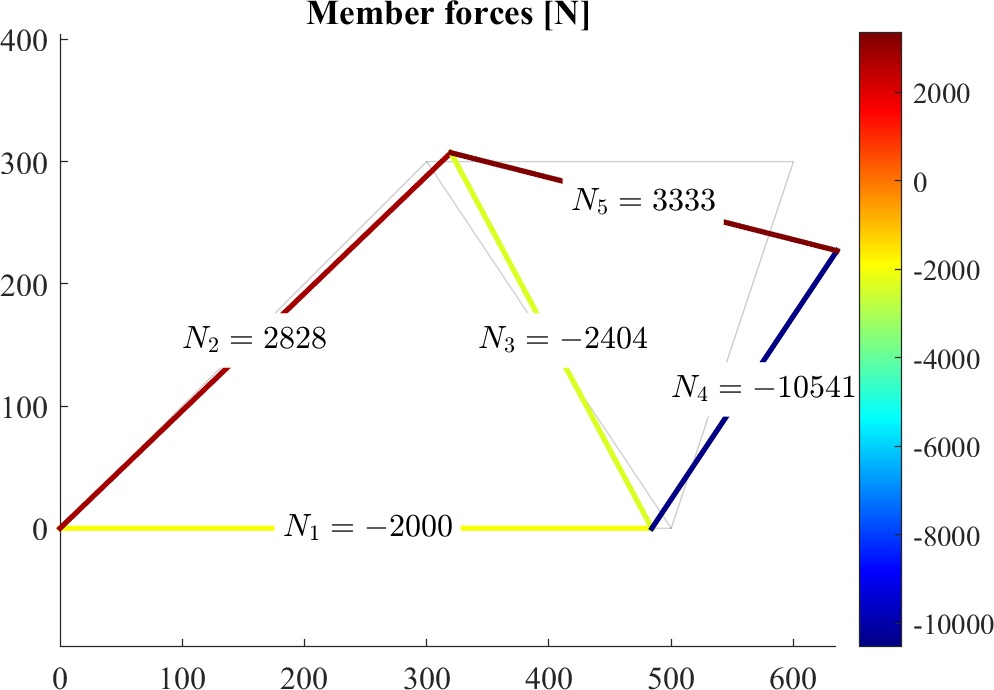

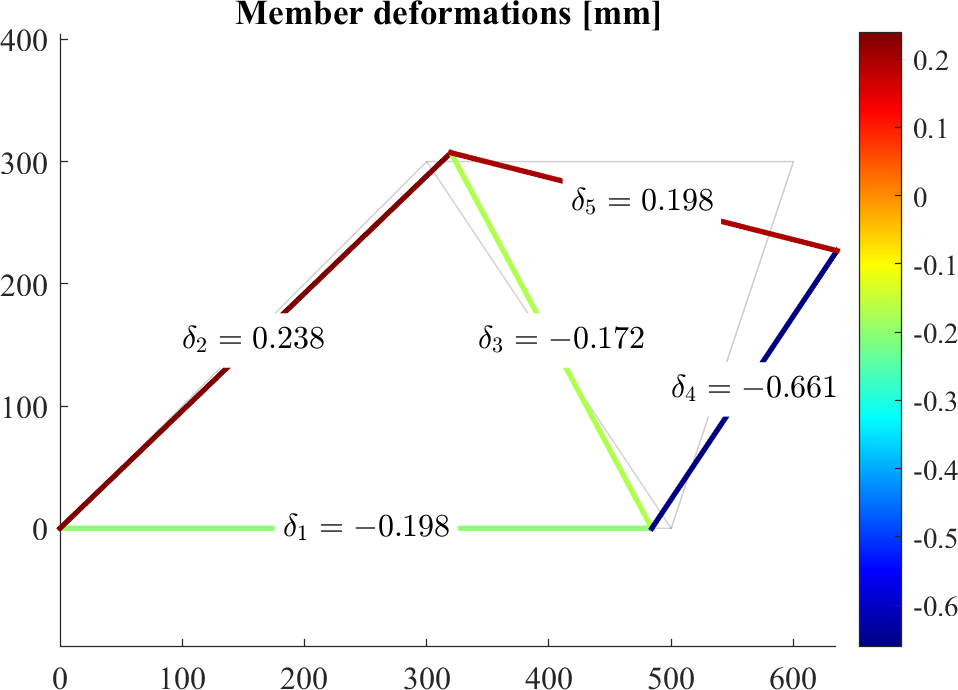

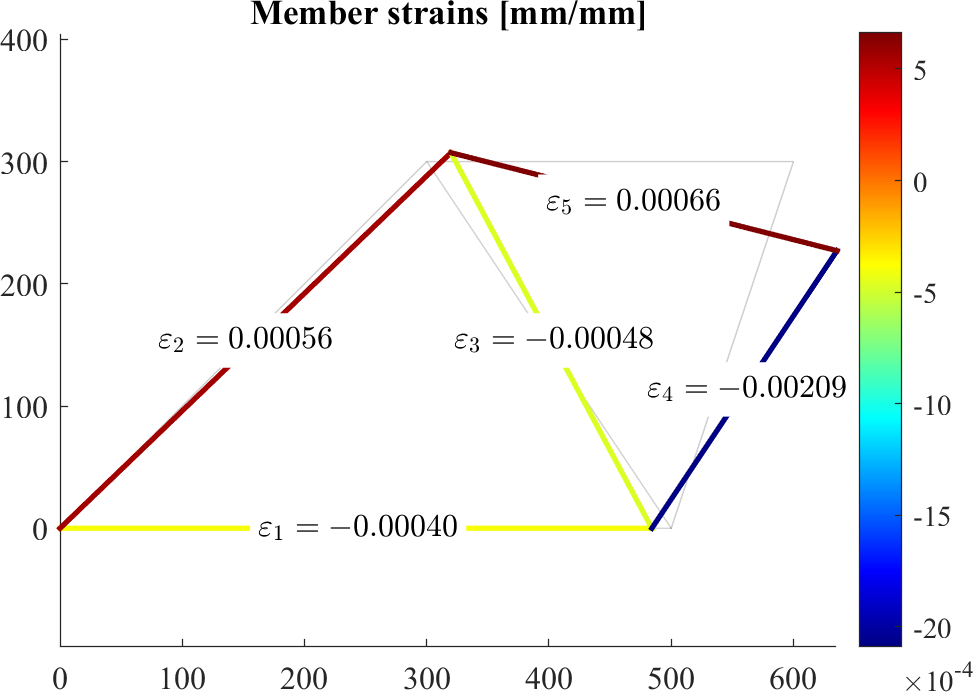

Computing rod quantities

Once the displacements have been computed we can compute the normal forces, resultant forces, deformations, strains and stresses.

React = zeros(dofs,1); % Reaction forces

delta = zeros(nele,1); % Deformation vector

N = delta; % Force vector

epsilon = delta; % Strain vector

sigma = delta; % Stress vector

for iel = 1:nele

inod = edges(iel,:);

ieqs = zeros(1,4); %[0 0 0 0]

ieqs(1:2:end) = inod*2-1;

ieqs(2:2:end) = inod*2;

iu = u(ieqs); % element displacements

p1 = P(inod(1), :);

p2 = P(inod(2), :);

r = p2-p1;

L = norm(r); % length of the bar

er = r/L; % direction, unit vector

c = er(1);

s = er(2);

T = [-c -s c s];

iA = A(iel); % element area

iE = E(iel); % element Young's modulus

k = (iA*iE/L); % element stiffness

idelta = T*iu; % element deformation

iN = k * idelta; % element force

fe = T'*iN; % nodal force

iepsilon = idelta/L; % element strain

isigma = iN/iA; % element stress

React(ieqs) = React(ieqs) + fe; % Add up all reaction forces

N(iel) = iN;

delta(iel) = idelta;

epsilon(iel) = iepsilon;

sigma(iel) = isigma;

end

React = [React(1:2:end), React(2:2:end)] % Reaction forces split into x and y componentsReact = 4x2

1.0e+04 *

0.0000 -0.2000

-0.0000 1.2000

0.0000 -0.0000

-0.0000 -1.0000Once the quantities of interest are computed, we will visualize them on the deformed structure. Since the displacements are typically very small, we will scale up the deformation in order to see a trend.

The quantities will be shown using a color field for a fast overview, but we will also add text boxes to give numerical values for more accurate reading.

scale = 80;

X = P(:,1); Y = P(:,2); Ux = U(:,1); Uy = U(:,2);

Xm = mean(X(edges')+Ux(edges')*scale,1);

Ym = mean(Y(edges')+Uy(edges')*scale,1);

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[sigma,sigma]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

text(Xm,Ym,cellstr(num2str(sigma)),'BackgroundColor','w')

title('Member stresses [MPa]')

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[N,N]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

text(Xm,Ym,cellstr(num2str(N)),'BackgroundColor','w')

title('Member forces [N]')

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[delta,delta]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

text(Xm,Ym,cellstr(num2str(delta)),'BackgroundColor','w')

title('Member deformations [mm]')

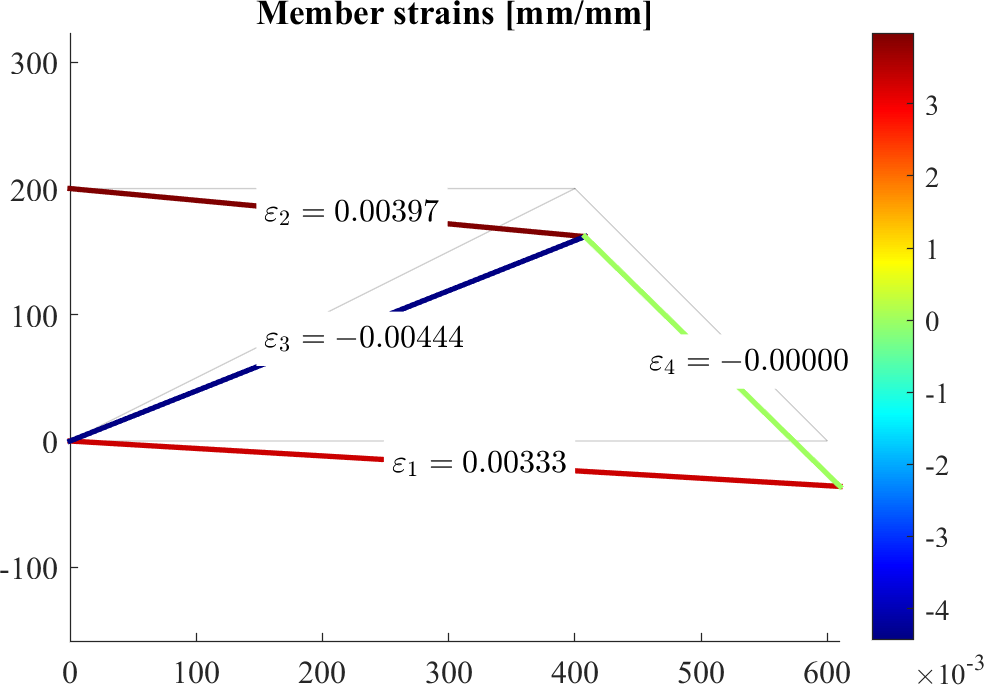

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[epsilon,epsilon]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

text(Xm,Ym,cellstr(num2str(epsilon)),'BackgroundColor','w')

title('Member strains [mm/mm]')

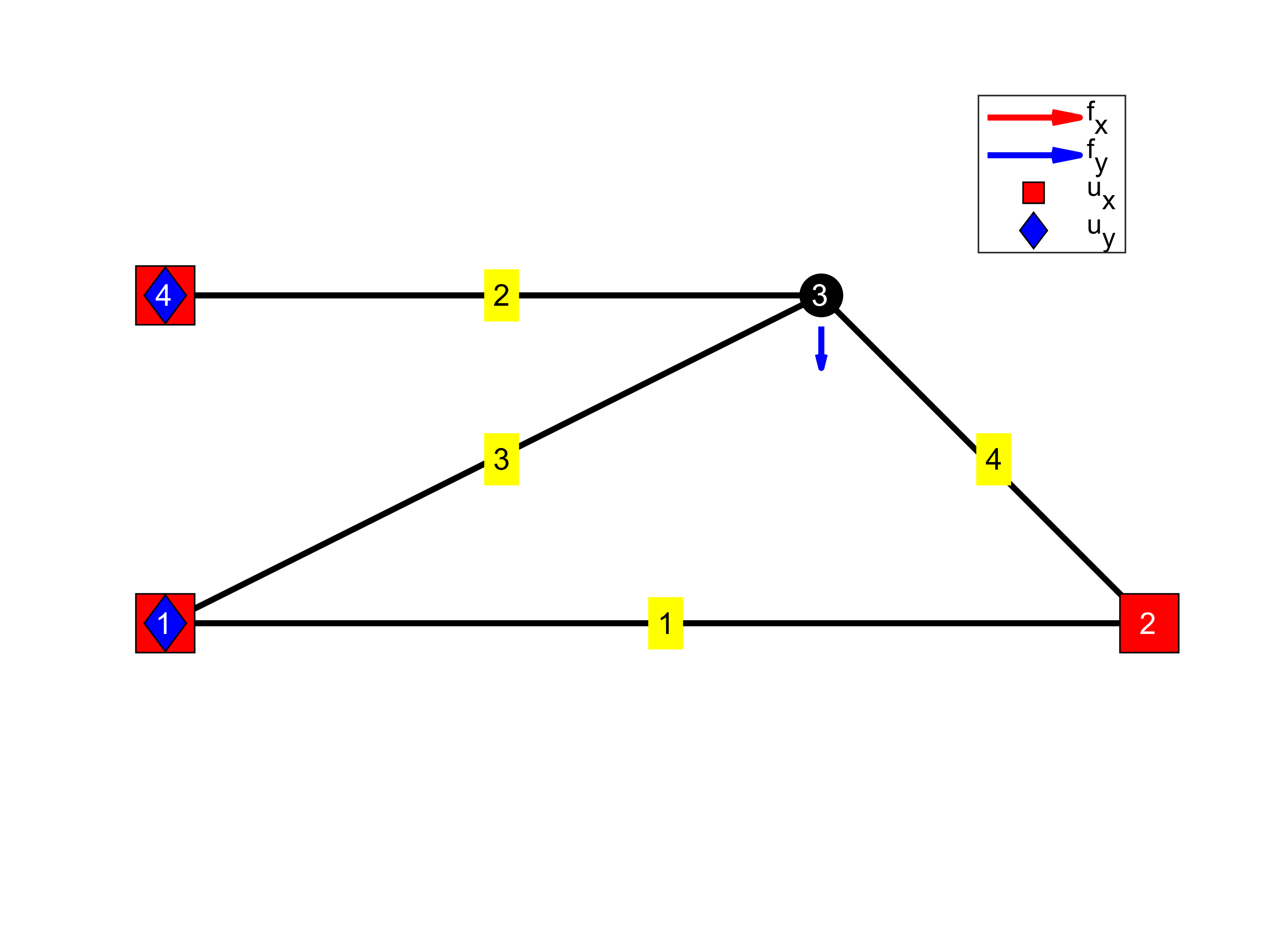

Here, in addition for nodal forces, we also have nodes with prescribed displacements which are non-zero. This is the same as deforming a spring to a certain length, it will correspond to a force, but we control the displacement instead.

mm. kN.

clear

P = [0 0

6 0

4 2

0 2]*100; % mm

nnod = size(P,1);

edges = [1 2

3 4

1 3

3 2];Initiate variables

nele = size(edges,1);

nnod = size(P,1);

dofs = nnod*2; %number of degrees of freedom

S = zeros(dofs, dofs);

f = zeros(dofs,1);

u = f;

Sprim = [1 0 -1 0

0 0 0 0

-1 0 1 0

0 0 0 0];

Ltot = 0; % Total length of the structure.Visualize the structure

figure; hold on

patch('Faces',edges,'Vertices',P,'LineWidth',2, 'HandleVisibility','off')

dx = max(P(:,1))-min(P(:,1));

dy = max(P(:,2))-min(P(:,2));

plot(P(:,1),P(:,2),'ok','MarkerFaceColor','k','MarkerSize',14, 'HandleVisibility','off')

text(P(:,1)-0.01*dx,P(:,2),cellstr(num2str([1:nnod]')),'Color','w', 'HandleVisibility','off');

axis equal

axis off

for i=1:nele

inod = edges(i,:);

xm = mean(P(inod,1));

ym = mean(P(inod,2));

text(xm,ym,num2str(i),'backgroundColor','y')

endUser defined parameters

E = 210000*ones(nele,1); % Young's modulus

A = 4*6*ones(nele,1); % Cross sectional area

presc = [1 2 3 7 8]; % prescribed degrees of freedom

u(presc) = [0, 0, 2, 0, 0]; %mm

f(3*2) = -10000;free = setdiff(1:dofs, presc); % Free DOFsVisualize the Load case

To visually verify load case and boundary conditions

px = presc(mod(presc,2)==1);

xinds = (px+1)/2;

py = presc(mod(presc,2)==0);

yinds = py/2;

Fx = f(1:2:end); Fy = f(2:2:end);

dd = sqrt(dx^2+dy^2);

quiver(P(:,1)+sign(Fx)*dd*0.03,P(:,2),Fx,zeros(nnod,1),0.08,'Color','r','LineWidth',2,'DisplayName','f_x')

quiver(P(:,1),P(:,2)+sign(Fy)*dd*0.03,zeros(nnod,1),Fy,0.08,'Color','b','LineWidth',2,'DisplayName','f_y')

plot(P(xinds,1),P(xinds,2),'sk','MarkerFaceColor','r','MarkerSize',25,'DisplayName','u_x');

plot(P(yinds,1),P(yinds,2),'dk','MarkerFaceColor','b','MarkerSize',14,'DisplayName','u_y');

text(P(:,1)-0.01*dx,P(:,2),cellstr(num2str([1:nnod]')),'Color','w','HandleVisibility','off');

legend show

Computing the stiffness matrix

for iel = 1:nele

inod = edges(iel,:);

ieqs = zeros(1,4); %[0 0 0 0]

ieqs(1:2:end) = inod*2-1;

ieqs(2:2:end) = inod*2;

p1 = P(inod(1), :);

p2 = P(inod(2), :);

r = p2-p1;

L = norm(r); % length of the bar

Ltot = Ltot + L;

er = r/L; % direction, unit vector

c = er(1);

s = er(2);

R = [c -s

s c];

% Transformation matrix

LT = [R, zeros(2);

zeros(2), R];

% Element stiffness matrix

iA = A(iel); % element area

iE = E(iel); % element Young's modulus

k = (iA*iE/L); % element stiffness

Se = k * LT*Sprim*LT';

S(ieqs,ieqs) = S(ieqs,ieqs) + Se ;

endNow we deal with the prescribed displacements.

fr = 8x1

1.0e+04 *

-1.6800

0

3.4619

-1.7819

-1.7819

1.7819

0

0f = 8x1

1.0e+04 *

1.6800

0

-3.4619

1.7819

1.7819

-2.7819

0

0u(free) = S(free,free)\f(free);

U = [u(1:2:end), u(2:2:end)]U = 4x2

0 0

2.0000 -7.1985

1.5873 -7.6112

0 0UR = sum(U.^2,2).^0.5 % Resultant displacementUR = 4x1

0

7.4712

7.7750

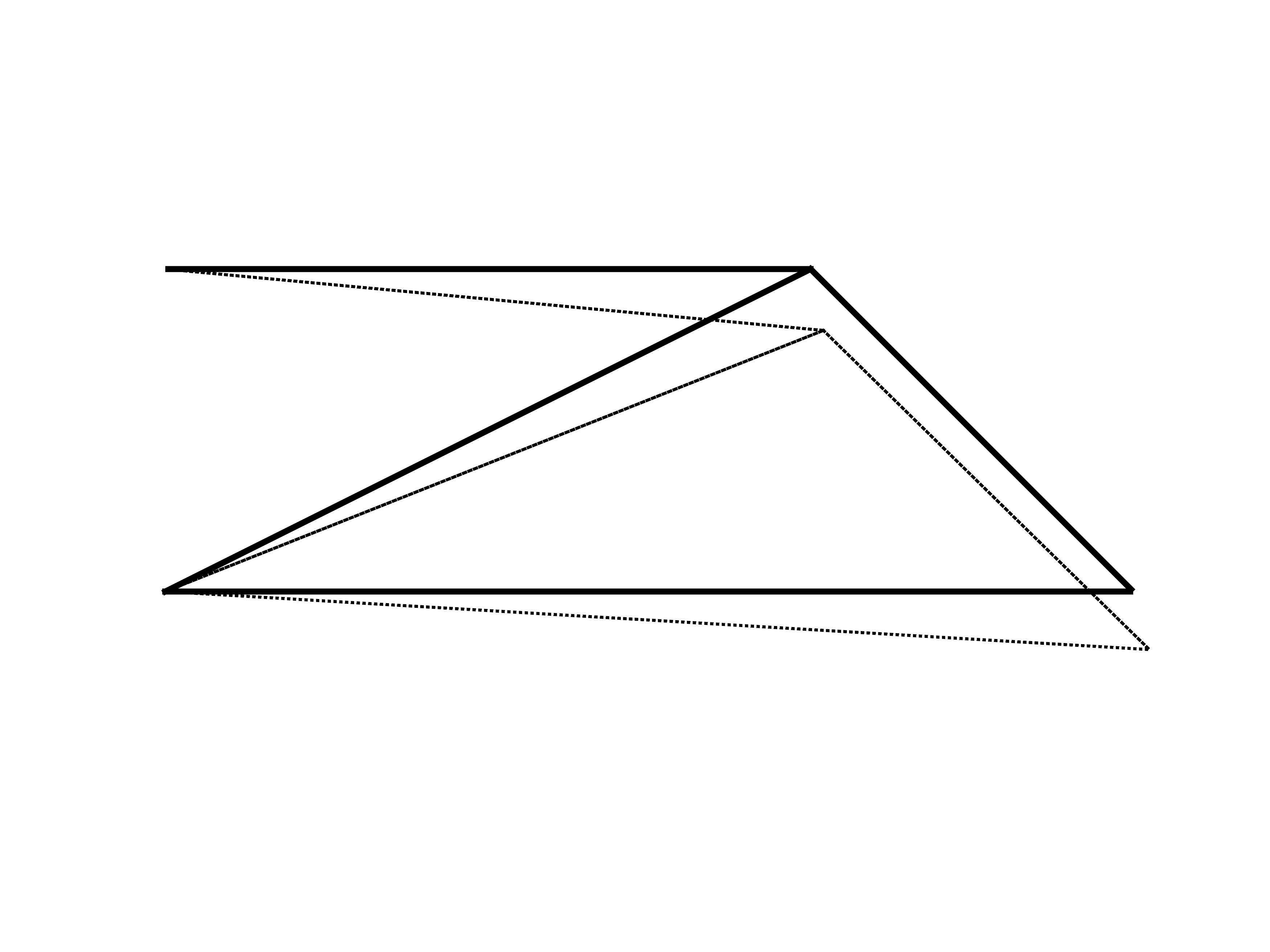

0Visualize the displacements

scale = 5;

figure

hold on

patch('Faces',edges,'Vertices',P,'LineWidth',2)

patch('Faces',edges,'Vertices',P+U*scale,'LineWidth',1,'LineStyle',':')

axis equal

axis off

Computing rod quantities

React = zeros(dofs,1);

delta = zeros(nele,1);

N = delta; epsilon = delta; sigma = delta;

for iel = 1:nele

inod = edges(iel,:);

ieqs = zeros(1,4); %[0 0 0 0]

ieqs(1:2:end) = inod*2-1;

ieqs(2:2:end) = inod*2;

iu = u(ieqs);

p1 = P(inod(1), :);

p2 = P(inod(2), :);

r = p2-p1;

L = norm(r); % length of the bar

er = r/L; % direction, unit vector

c = er(1);

s = er(2);

R = [c -s

s c];

% Transformation matrix

LT = [R, zeros(2);

zeros(2), R];

T = [-c -s c s];

iA = A(iel); % element area

iE = E(iel); % element Young's modulus

k = (iA*iE/L); % element stiffness

idelta = T*iu;

iN = k * idelta;

fe = T'*iN;

iepsilon = idelta/L;

isigma = iN/iA;

React(ieqs) = React(ieqs) + fe;

N(iel) = iN;

delta(iel) = idelta;

epsilon(iel) = iepsilon;

sigma(iel) = isigma;

endThe reaction forces in each node.

React = [React(1:2:end), React(2:2:end)]React = 4x2

1.0e+04 *

0.3200 1.0000

1.6800 0.0000

0.0000 -1.0000

-2.0000 0Visualize color fields

X = P(:,1); Y = P(:,2); Ux = U(:,1); Uy = U(:,2);

Xm = mean(X(edges')+Ux(edges')*scale,1);

Ym = mean(Y(edges')+Uy(edges')*scale,1);

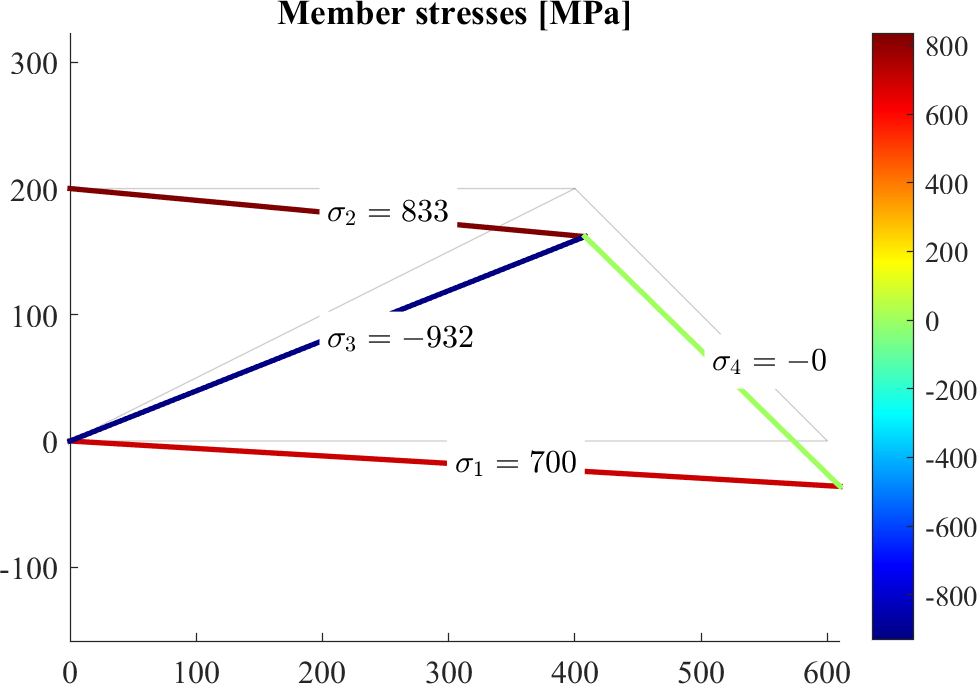

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[sigma,sigma]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

for iel=1:nele

text(Xm(iel),Ym(iel),sprintf('$\\sigma_{%d}=%0.0f$',iel,sigma(iel)),'BackgroundColor','w','Interpreter','latex')

end

title('Member stresses [MPa]')

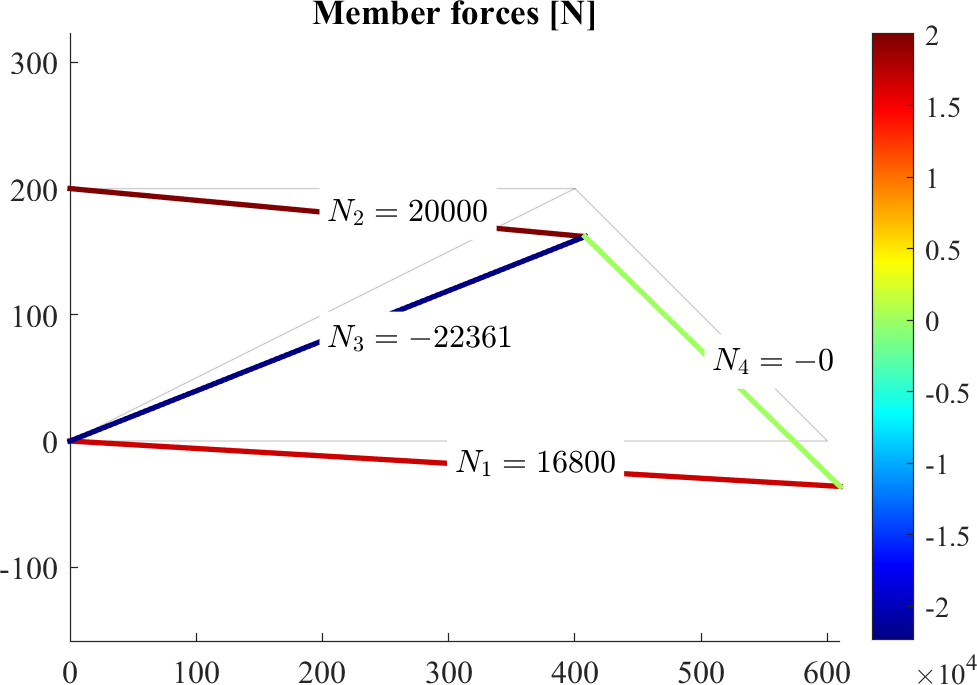

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[N,N]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

for iel=1:nele

text(Xm(iel),Ym(iel),sprintf('$N_{%d}=%0.0f$',iel,N(iel)),'BackgroundColor','w','Interpreter','latex')

end

title('Member forces [N]')

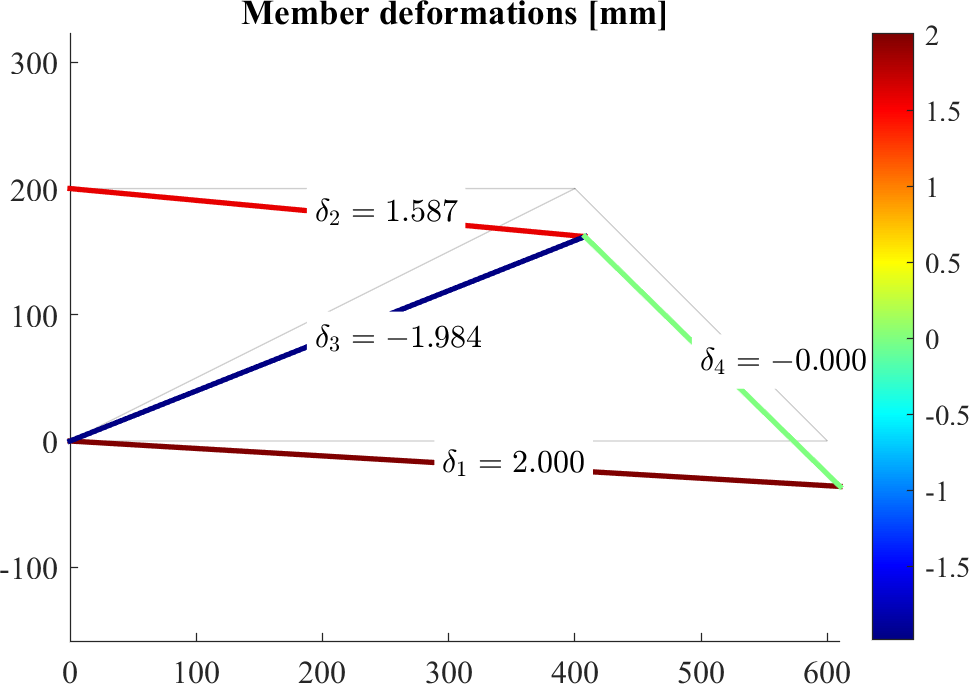

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[delta,delta]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

for iel=1:nele

text(Xm(iel),Ym(iel),sprintf('$\\delta_{%d}=%0.3f$',iel,delta(iel)),'BackgroundColor','w','Interpreter','latex')

end

title('Member deformations [mm]')

figure; hold on

patch('Faces',edges,'Vertices',P,'EdgeAlpha',0.1)

patch(X(edges')+Ux(edges')*scale,Y(edges')+Uy(edges')*scale,[epsilon,epsilon]','EdgeColor','flat', 'LineWidth',2)

axis equal

colormap jet; colorbar

for iel=1:nele

text(Xm(iel),Ym(iel),sprintf('$\\varepsilon_{%d}=%0.5f$',iel,epsilon(iel)),'BackgroundColor','w','Interpreter','latex')

end

title('Member strains [mm/mm]')